Industrial Automation

October 21, 2025

Navigating the Evolution between Yesterday and Today

Navigating the Evolution between Yesterday and Today

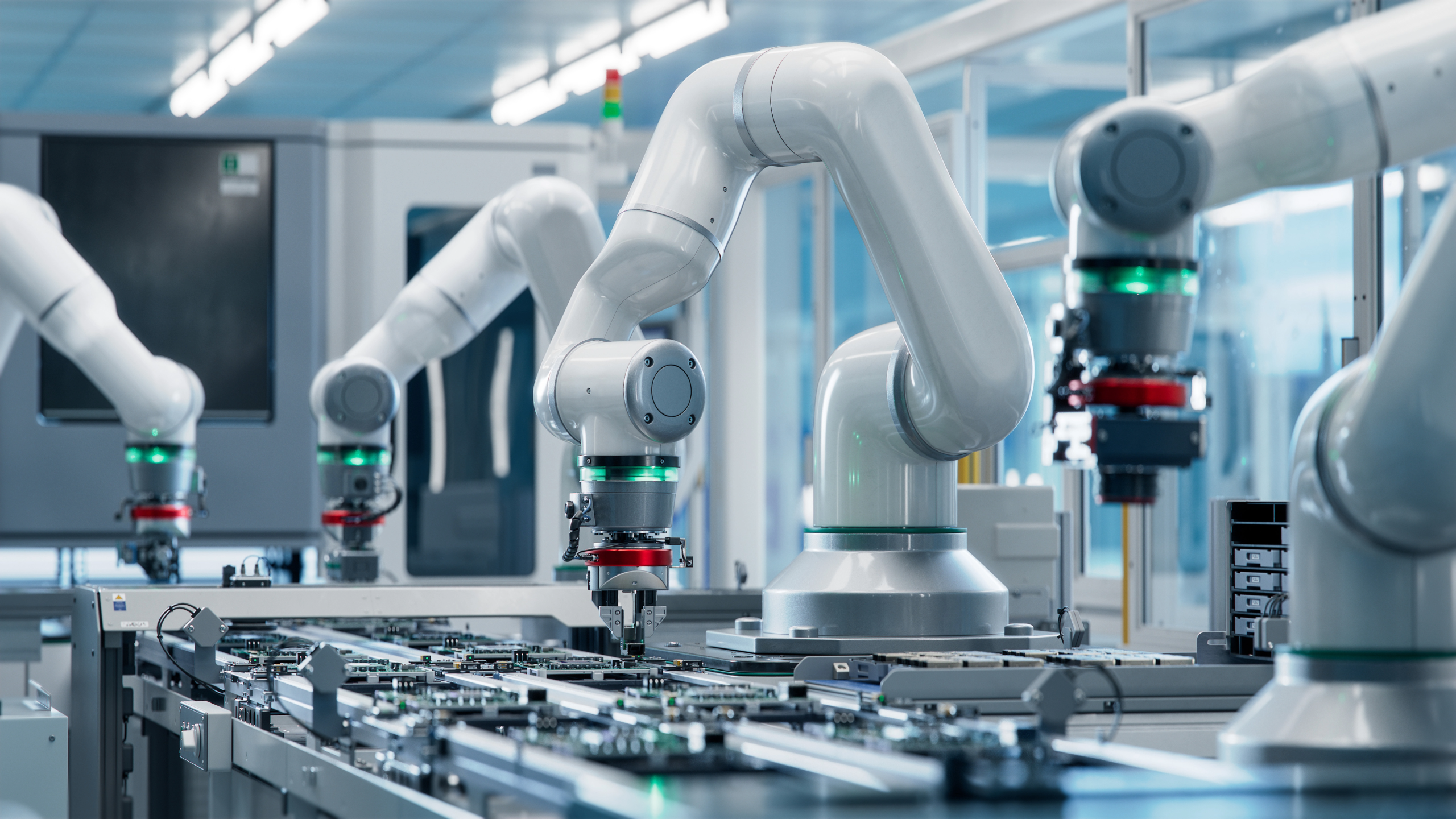

Industrial automation has been a significant game-changer in the manufacturing industry over the past decades. From the early days of the Industrial Revolution to the modern era of advanced technology, the evolution of industrial automation propelled forward innovations and trends that will reshape the sector's future. The progression of industrial automation began with manual labor and basic mechanical systems, like conveyor belts, gradually evolving with early electrical control systems. However, introducing digital computer and PLC revolutionized the industry, enabling precise and flexible automation through programmable logic and sensor integration. The shift to "smart" manufacturing has enabled manufacturers to optimize processes, reduce downtime, and improve product quality.

Nowadays, a new concept is introduced by converging automation and artificial intelligence (AI) into the production line. This intelligent system is now capable to solve sophisticated algorithms while adapting to any new situation autonomously. For example, robot integration, which can be collaborative robotics (COBOT) to work next to humans reducing the skilled worker shortage impact or autonomous robots to replace workers in hazardous environments minimizing accidents and human errors. In addition, AI in image processing systems plays a crucial role with tasks like production line inspection and quality control.

Machine learning is accelerating these trends by making AI systems more human-like. To perform this task, a large dataset should be created. The growth of the Internet of Things (IoT) and the interconnection of devices and equipment within a smart network facilitate real-time monitoring of all critical parameters. This can help the implemented system make more informed decisions and create predictive maintenance strategies, aiming for zero downtime of the plant and reducing maintenance costs. Many software companies are racing to create the best smart systems to manage plant resources and waste, like ERP, PMS, and many others. These software solutions also need a large database while maintaining fast data access and ensuring the confidentiality and integrity of the collected information. Here lies the importance of advancements in cloud computing, edge computing, blockchain, and cybersecurity simultaneously. In simple terms, cloud computing is provided as a scalable and flexible service over the internet by cloud providers (e.g., AWS, Google), eliminating the need for companies to manage their own data centers. Edge computing is revolutionizing data processing speeds and reducing latency by bringing information storage and computing abilities closer to the devices that produce that information. A blockchain is a time-stamped series of data records managed by multiple computers owned by different entities. Each of these blocks of data is secured and bound to each other using cryptographic principles, ensuring data integrity and transparency. It is like collecting puzzle blocks to form the final image. Cybersecurity safeguards systems, networks, and data from attacks and unauthorized access. It encompasses a range of strategies and technologies designed to defend against cyber threats, which include malware, phishing, ransomware, and other malicious activities. In 2024, industrial automation will continue to prioritize sustainability. Efforts to improve efficiency and minimize environmental impact will lead to the development of technologies focused on reducing natural resource consumption, cutting waste, and implementing sustainable practices across the production process.

Final Thoughts

Final Thoughts

Finally, the industrial automation landscape in 2025 will be characterized by the integration of advanced technologies, a commitment to efficiency and sustainability, and the acknowledgment of collaboration between humans and machines. As businesses strive to stay competitive in a constantly evolving global market, the strategic and thoughtful adoption of automation solutions will be crucial for driving growth and fostering innovation in the industrial sector.

Empowering the Next Generation

October 15, 2025

Raymond Feghali Co. for Trade and Industry's Commitment to Engineering Education and Innovation

At Raymond Feghali Co. for Trade and Industry (RTF), we believe that the future of industry lies in the hands of the next generation. With this vision at our core, RTF has established itself not only as a leader in trade and industrial innovation but also as a driving force in educational development and youth empowerment across Lebanon and the region.

Read More

Partners & Collaborations

October 10, 2025

OEMs Trust Raymond Feghali Co. as a Leading Supplier for Industrial Solutions in Lebanon and Beyond

For over five decades, Raymond Feghali Co. for Trade & Industry (RTF) has earned its reputation as a key supplier and partner to Original Equipment Manufacturers (OEMs) across Lebanon and the region. With a steadfast commitment to quality, innovation, and reliability, RTF has become a cornerstone in the supply chain for companies that design and build advanced industrial, mechanical, and automation systems.

Read More

Partners & Collaborations

September 5, 2025

USEK and Raymond Feghali Co. Sign MOU to Strengthen Academia-Industry Collaboration in Industrial Innovation

The Holy Spirit University of Kaslik (USEK) has signed a Memorandum of Understanding (MOU) with Raymond Feghali Co. for Trade & Industry, marking the beginning of a strategic collaboration aimed at advancing industrial automation, power transmission, and technical innovation in Lebanon.

Read More

Raymond Feghali Co.

Roumieh old main Road-Industrial zone Beirut – Lebanon

Raymond Feghali Co.

Roumieh old main Road-Industrial zone Beirut – Lebanon

Tel: +961 1 893176/ 1 894545

E-mail: info@rtf-co.com